The objective of this project is to incorporate digital fabrication in traditional craft practices. The next two projects do so by combining laser cutting with the craft of last making and clog making.

LASTS

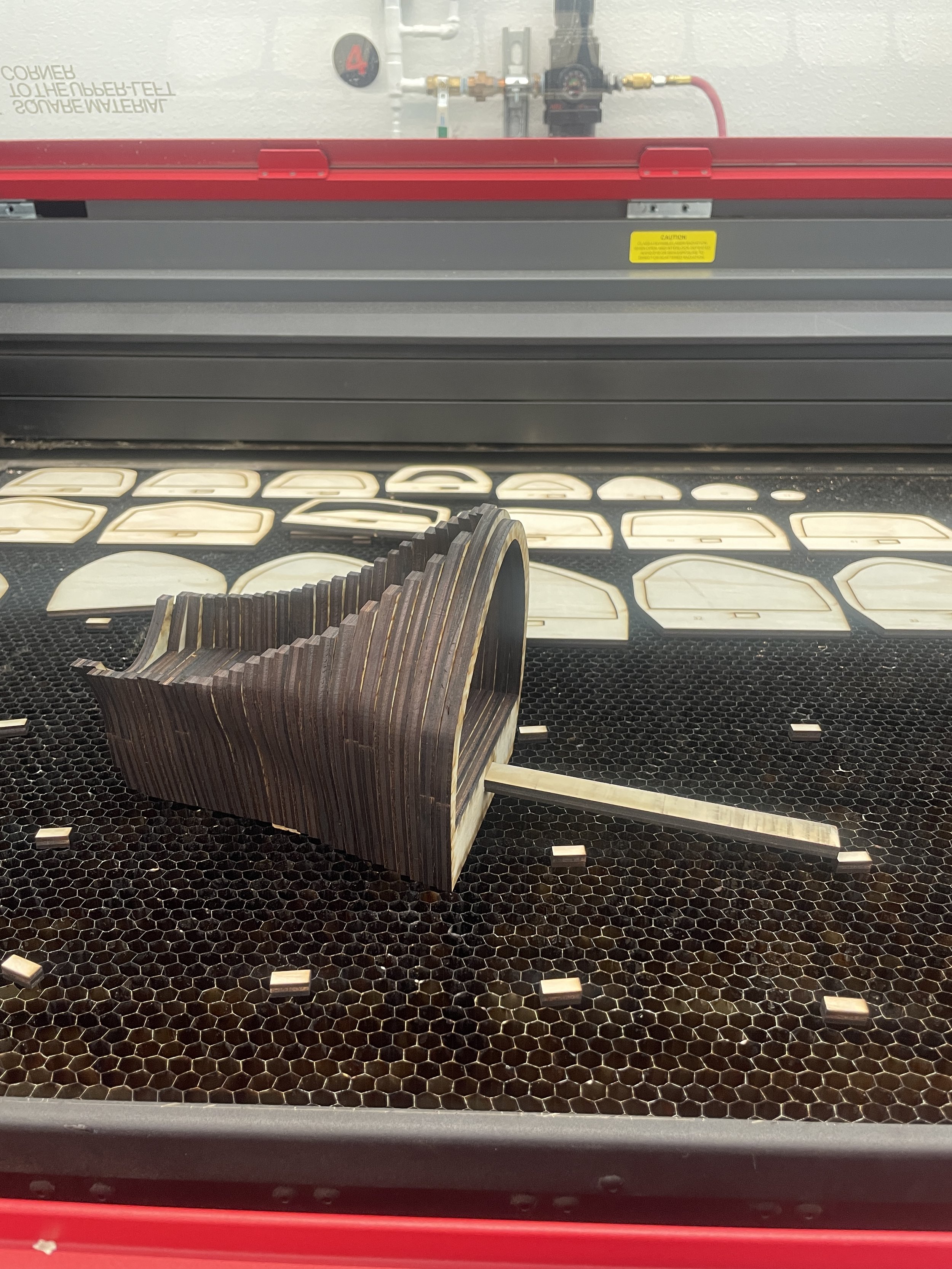

Traditional shoe last making is a skilled craft that involves making wooden forms to create the shape and size of shoes. These lasts serve as the foundation for shoe construction, dictating the shoe's fit and design. Artisans use age-old wood carving techniques to produce these lasts. I began my process by first 3D modeling a shoe last and then dissected that model into vectors that served as the foundation for creating cross-sectional slices of the last. These sections were laser-cut and reassembled using PVA glue and a wooden key, which maintained the alignment of each cross-section. I then used a series of sanders to get a smooth finish on the last.

CLOGS

Traditional wooden clogs are known for their thick wooden soles and often open-back design. They have a rich historical legacy and exhibit unique styles and variations across diverse cultures worldwide. The process of making the clogs was very similary to the process of making the shoe lasts. To celebrate the use of digital fabrication, I chose not to sand the cross-sectional edges smooth. This experiment illustrates how various fabrication techniques can significantly influence both the aesthetics and functionality of the final product.